How to choose excavator bucket teeth is a difficult problem to solve. Using the right excavator teeth can not only prolong the life of the bucket teeth. but also save the beginning. It can also greatly improve the working efficiency of the excavator.

About the selection of excavator bucket teeth, we need to consider many factors. Based on our years of experience in producing excavator’s teeth, we have summarized the following aspects. If you are looking for the right bucket teeth for your project, here are a few factors to consider.

Excavator Bucket Teeth Producing Method

Casting bucket teeth

Casting bucket teeth is a popular excavator tooth manufacturing technology. The production process of casting bucket teeth is not complicated, and bucket teeth with high wear resistance and impact resistance can be produced. Of course, stronger excavator teeth can also be produced if some specific materials are used with special casting techniques. Compared with forged bucket teeth, casting bucket teeth are less expensive to manufacture.

Although the process of casting bucket teeth is not complicated, if the process is not up to standard, the bonding strength of the material will be reduced, which will affect the quality of the bucket teeth.

The material of casting bucket teeth is usually austenitic ductile iron, and it can also be low alloy steel. The main elements of low alloy steel are nickel and molybdenum.

Forged bucket teeth

Forged bucket teeth are made of heat-treated alloy steel. But every tooth manufacturer uses a different type of steel. To improve wear resistance and impact resistance. Materials such as carbon steel, chrome steel, nickel steel and molybdenum steel are usually chosen.

Compared with cast teeth, forged teeth have higher durability and tensile strength. At the same time, the price of forged bucket teeth is also higher.

When working in harsh environments. Excavators and backhoes can use higher-strength forged bucket teeth.

By Excavator bucket tooth material

Different types of excavator bucket teeth select different excavator materials. The harder the material of the excavator teeth, the better its wear resistance and impact resistance, and the longer the service life.

Commonly used excavator tooth materials include high manganese steel bucket teeth, low carbon alloy bucket teeth and high chromium cast iron bucket teeth. Each material has its own characteristics:

High manganese steel bucket teeth:

High manganese steel has good toughness and wear resistance under work hardening conditions. At present, the vast majority of excavator teeth use high-energy steel materials.

Low carbon alloy bucket teeth:

low alloy steel has good toughness and wear resistance is 1-3 times higher than that of high manganese steel. Low carbon alloy bucket teeth have low cost and long service life.

High-chromium cast iron bucket teeth:

High-chromium cast iron has high wear resistance, but it has poor toughness and is not resistant to impact.

By Excavator bucket tooth structure

According to the bucket tooth seat of the excavator, the bucket teeth can be divided into two structures:

direct-mounted bucket teeth and horizontal-mounted bucket teeth.

Direct mount bucket teeth

The finger pin shaft of the direct-mounted bucket tooth is installed perpendicular to the front of the excavating tooth. The tooth pins of the direct-mounted bucket teeth are easy to be squeezed during excavation work. So, if the digging force is large, it is easy to cause the tooth pin to fall off. Direct mount bucket teeth are commonly used in mini excavators.

It is more convenient to disassemble, smash directly from above, and the operation space is large. When excavating, the directly mounted tooth pin will be squeezed by the excavated material on the front. If the digging force is large, the clamping force of the expansion spring cannot meet the requirements, which will easily cause the tooth pin to fall off.

Horizontal bucket teeth

The horizontally mounted bucket tooth pin shaft is installed parallel to the front face of the excavating bucket tooth. There will be no squeezing force on the front of its tine pin. So, the horizontally mounted bucket teeth can withstand larger digging forces. Horizontally mounted bucket teeth are generally used in excavators with a digging force of more than 20 tons.

If your project requires a larger digging force, it is recommended that you choose a horizontally mounted bucket tooth.

Indifferently, the tooth seats of different brands of excavators are also different. Such as Komatsu excavators, Carter excavators, Daewoo excavators, Kobelco excavators. They use cross pin teeth.

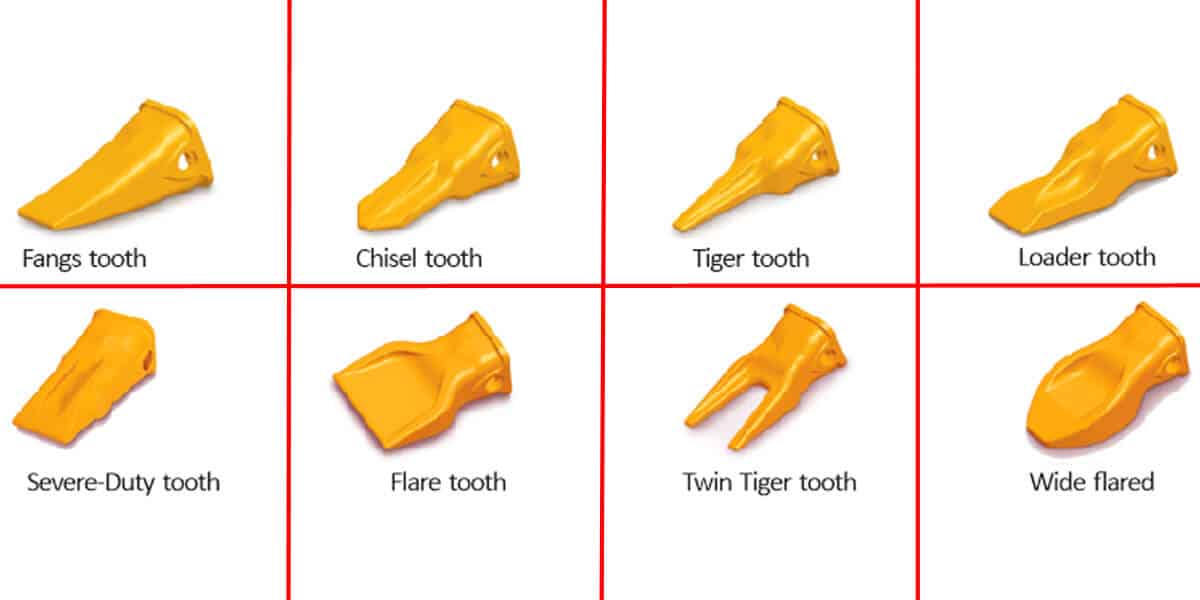

By Excavator bucket tooth classification

Depending on the working environment of the excavator, there are also many types of bucket teeth. Each type of bucket tooth can be used for a specific excavation job.

Standard Long Bucket Teeth

Standard long bucket teeth is a kind of multi-purpose bucket teeth. Standard long bucket teeth can be used in many work environments.

Rock Chisel Bucket Teeth

Rock chisel bucket teeth are also more commonly used bucket teeth. Its shape increases the penetration of the bucket teeth,

Ideal for use in mines, rock or hard ground.

Tiger Long Bucket Teeth

tiger long bucket teeth offer a sharp narrow point, which allows for greater penetration. tiger long bucket teeth can be used for digging environments such as frosty ground and rocks.

Heavy-duty Long Bucket Teeth

It is like standard long bucket teeth. It has better wear resistance and is the most wear-resistant of all excavator teeth.

Twin Tiger Bucket Teeth

The twin tiger bucket teeth, like the tiger long bucket teeth, are used in tougher environments. It can provide two sharp points. If bucket side clearance is required, use twin tiger bucket teeth instead of tiger long bucket teeth.

Rock Penetration Bucket Teeth

The design of Rock Penetration bucket teeth provides it with maximum wear resistance and good penetration.

Flat Penetrator Bucket Teeth

When excavators and backhoes are excavating relatively hard objects, Flat penetrator bucket teeth provide good penetration and excavation performance.

By excavator brand and bucket tooth size

Each brand of excavator has its own specifications of bucket teeth. In addition to choosing the general bucket teeth, you can choose the appropriate bucket teeth according to the brand model of your excavator.

If you don’t know the brand and model of your excavator, you can determine the size of the bucket teeth by measuring the size of the pin and cage. Of course, the size of the bucket teeth can also be determined by measuring the size of the tooth sleeve.

As a manufacturer of excavator bucket teeth, we can make bucket teeth for various models of excavators. At the same time, we can also customize excavator teeth according to customer requirements. Bucket tooth size, material, color, shape, etc. can be customized.

If you are not sure what excavator teeth your project needs, you can consult us. We will provide customers with the best solution.