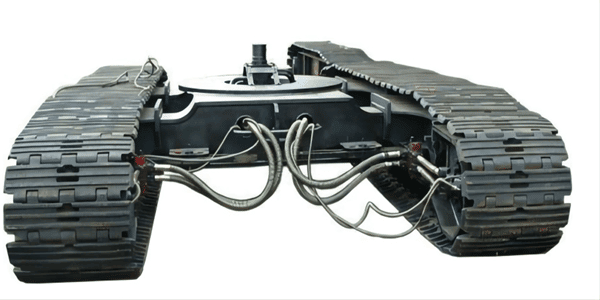

If you have been exposed to excavators, you will understand that the structure of excavators is very complex. It includes many parts. Such as excavator circuits, generators, hydraulic systems, transmissions, and undercarriage. There are also various other small devices and screw installations.

As indispensable construction equipment. Excavators have heavy workloads and harsh construction environments. So, failures in work are also unpredictable. So, this requires that we must maintain it in a timely manner in our daily work. Among them, undercarriage maintenance is one of the key points of excavator maintenance.

We are an excavator undercarriage parts manufacturer from China. Here are some contents about undercarriage maintenance.

Many people like to use working hours to measure the service life of equipment. But, the life of an excavator undercarriage does not depend on its use time. It depends on the usual maintenance and various factors encountered in the work.

Clean the undercarriage

undercarriage cleaning is the easiest and most controllable way to reduce undercarriage wear. The undercarriage is a very complex moving part. There will be many complex road conditions during the work process. If it is not cleaned in time, dirt will accumulate and cause accelerated wear and tear of undercarriage components. If the undercarriage is not cleaned for a long time, the dirt will harden. At the same time, it will also cause the undercarriage parts to be stuck and the crawler track to be blocked, reducing fuel efficiency and causing unnecessary economic losses.

Here are also a few undercarriage cleaning tips for your reference:

1 At the end of each job, complete a simple undercarriage cleaning immediately

2 Use a dedicated crawler shovel to dig out hard dirt and rocks.

3 Regular cleaning of components and release of grit

4 Use compressed air to inject into the bottom assembly of the excavator.

Excavator undercarriage cleaning can take a lot of your time, and it’s well worth it. Keeping the undercarriage clean will save you a lot of time and money. It is also an important step in undercarriage maintenance.

Application Position

The types of work of excavators include digging, dozing, turning, loading, carrying, and leveling. Certain jobs put more stress and weight on the undercarriage. Generally, the heavier the weight is, the more the undercarriage will grind.

Besides to the type of work, the working terrain of the excavator also affects the wear of the undercarriage. For example it might work on hillsides, slopes, crests and depressions. So, it is also necessary to preset the working terrain to adjust the state of the landing gear.

Regular maintenance and inspection plan

Regular maintenance and inspection plans are very important for excavator undercarriage maintenance. Through regular maintenance and inspection of the undercarriage, problems can be found and repaired in time to avoid unnecessary losses.

Here are some suggestions for regular inspection and maintenance of the undercarriage:

- 1 First, check the following items for missing and damaged parts that are not suitable. These items include: drive motors, drive sprockets, rock guards, track chains, track shoes, rollers, guide wheels, drive wheels, etc.

- 2 Check the rollers, idlers and drives for oil leaks. If there is oil leakage, it should be dealt with in time. Failure to do so could result in major failure of the rollers, idlers or track drive motors.

- 3Refer to the equipment manual, check the track tension and adjust it according to the environment in which the machine is used.

- 4 Test drive the excavator and look for any performance issues.

- 5 If the machine is often used in harsh environments, it is necessary to increase the number of inspections.

Creating and adhering to a regular maintenance and inspection schedule is critical to keeping your excavator undercarriage in good condition. If problems are found during inspection, repair or replace damaged, missing and excessively worn parts in a timely manner.

Track maintenance

Track maintenance for tracked machines is more agreeable to ignore. Track maintenance generally includes two conditions: track tension and preventing track misalignment.

Track Tension:

Incorrect track tension has an effect on track wear. Tight tracks, for example, can significantly increase wear. It is important to maintain proper track tension to reduce wear.

Typically, when working in soft, muddy conditions, it is advisable to run the track a little looser. If the rail is too tight or too loose, it will rapidly accelerate wear.

Prevent track misalignment:

Visually check that the tracks and idlers are not properly aligned before running the machine. Alignment can also be checked against wear patterns on the rollers and idlers. We prevent track misalignment through regular inspections.

Also, keep the track properly tensioned. Loose rails can cause the rails to be misaligned.

Maintenance of tracks should not be neglected. If the track is not maintained for a long time, it will cause more wear on the contact area with the teeth, idlers, rollers and sprockets.

Personnel operation

The skill and experience of the excavator operator plays an important role in reducing undercarriage wear. For example, clever operators can adjust the speed according to ground conditions. It is also known that part stress can be reduced by means of probe positioning. Therefore, the necessary training for excavator operators is provided. Can extend the life of crawler machines. And can reduce maintenance and repair costs.

Here are some tips on how to reduce wear and tear on your excavator:

- 1 During the operation of the excavator, obstacles and uneven ground should be avoided.

- 2 Minimize time on slopes. Prolonged operation on sloped ground increases wear on the rollers, idlers and guide lugs.

- 3 Minimize driving speed. As the speed of the excavator increases, it also increases the wear on the bushing, sprocket and pin.

- 4 places reduce reversing, and the crawler of the excavator is set to wear less when driving forward.

- 5 Make wider turns. Sharp turns of the excavator can accelerate wear and make it more likely to derail the excavator.

The above are just some simple operating suggestions, and a smart operator will grasp more of the nuances of machine operation, which can keep equipment running longer with minimal maintenance and repair costs. So, the training of machine operators is also a very necessary investment.

Maintenance of undercarriage parts

Although the wear of the undercarriage components cannot be eliminated. But their lifespan can be extended by maintaining them regularly. The main parts of the undercarriage that need to be maintained are the rollers, sprockets, guide wheels, sprockets and tracks. Let’s talk about how they are maintained.

Rollers

The maintenance of the rollers should pay attention to avoiding long-term immersion in muddy water. When completing a certain job, the dirt on the rollers should be cleaned up and the rollers should be kept dry.

The seal between the roller and the shaft is most afraid of freezing and scratching, which will cause oil leakage. So, special attention should be paid to these problems in winter.

The damage of the rollers will cause many failures, such as: walking deviation, walking weakness, etc.

carrier roller

The carrier wheel is an important tool to ensure that the excavator can walk in a straight line. If the carrier roller is damaged, it will cause your excavator to go off-track.

The carrier roller needs to be injected with lubricating oil. If oil leakage is found, it means that a new carrier roller needs to be updated. So usually we should pay more attention to the cleaning above. Avoid solidified soil hindering the work of the carrier roller.

Guide wheel

The guide wheel is composed of a guide wheel and a tension spring, and is an important tool to keep the excavator moving forward.

If the guide wheel is broken, it may cause friction between the chain rails, so this guide wheel is also a very important maintenance site.

When the excavator is running and walking, keep the guide wheel in front. This avoids abnormal wear of the chain rails. The tension spring can also absorb the impact brought by the road surface during work and reduce wear.

sprocket

The sprocket is located behind the X frame, and it is directly fixed on the X plus without shock absorption. If the sprocket travels forward, it will not only cause abnormal wear on the drive ring gear and chain rail. It will also have an adverse effect on the X frame, and the X frame may have problems such as early cracking.

In order to prevent these problems, we should always open the sprocket guard to clean the dirt inside. This can avoid excessive dirt accumulation and wear on the oil pipe of the travel motor.

track

The track is mainly composed of track shoes and chain link. At the same time, according to the different application sites, the track shoes can be divided into reinforced plates, standard plates and extension plates. Reinforcing plates are mainly used in mining conditions, standard plates are used in earthwork conditions, and lengthened plates are used in wetland conditions.

The wear of the track shoes in the mine is serious. When walking, the gravel will sometimes get stuck in the gap between the two shoes. When it comes into contact with the ground, the two shoes will be squeezed, and the track shoes will easily bend and deform. , Long-term walking will also cause cracking problems at the bolts of the track shoes.

The chain link is in contact with the driving ring gear and is driven by the ring gear to rotate. Excessive tension of the track will cause early wear of the chain link, ring gear and idler pulley. So, according to different construction road conditions, it is necessary to adjust the tension of the crawler.

Some of the tips summarized above are only part of the maintenance of the excavator undercarriage. No device can be used forever. If you follow these tips above to maintain the undercarriage, and maintain good operating practice, correct maintenance measures. Your excavator undercarriage will exert greater performance and service life. And it will save a lot of maintenance costs later.

As a supplier of excavator undercarriage parts, we can provide support rollers, carrier rollers, idlers, sprockets and bucket teeth for excavator undercarriage. If you have any needs, you can contact us at any time by email (info@001machine.com) us.