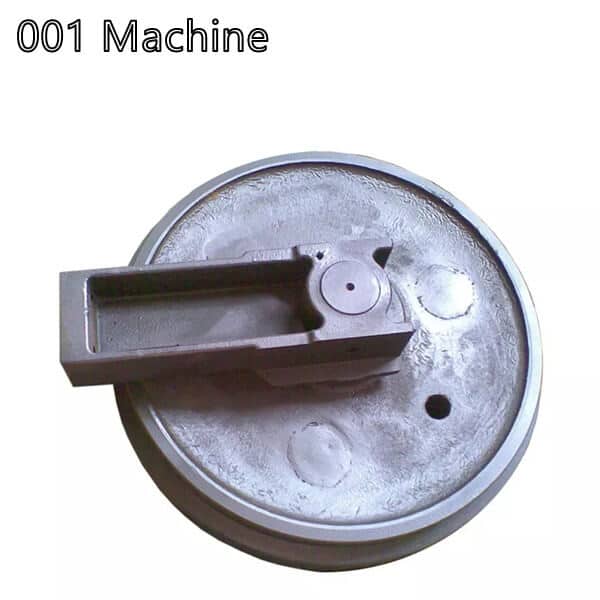

Customized Front Idler Manufacturing for sale

- Logo: 001 Machine,As your requirement

- Material: 50Mn,40Mn,35Mn,other alloy steel

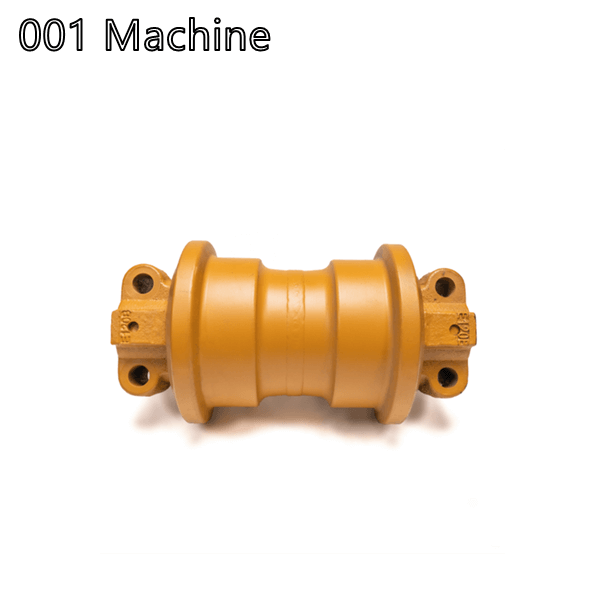

- Colors: Black&yellow, or customized

- Finish: Smooth

- Technique: Forging, Casting, Machining, Heat Treatment

- Surface Hardness: HRC50-56

- Depth:8-12mm.

Description

In the landing gear of excavators and bulldozers, the front idler is located at the front or rear of the landing gear. It enables the equipment to move forward or backward and maintain the correct direction.

Front idlers work with tensioners. Their main function is to keep the track in proper tension and prevent the track from falling off. Enables equipment to traverse rugged and challenging terrain.

Characteristic

- Our front idler shells are made of high-quality alloy steel and have been heat treated. The product has a long wear life and stress resistance.

- The needles are also heat treated to ensure good hardness and adapt to harsh working conditions.

- We adopt the finishing process to make the front idler smooth in surface and accurate in size. It can perfectly match various brands of excavators and bulldozers.

Applications

Our front idlers can be applied to excavators, bulldozers and other undercarriage machines of various brands and models. At the same time, we can also customize front idlers according to customer needs