Users of excavators and loaders must encounter situations where bucket teeth need to be replaced. Usually, they must be curious about the function of bucket teeth. What kind of bucket teeth do you want to buy when replacing bucket teeth? Today we will talk about the bucket teeth.

What are bucket teeth?

Excavator bucket teeth are the main vulnerable parts of excavators. Like human teeth. They are composed of a tooth base and a tooth tip. The two are connected by a pin. Because the wear and tear of the bucket tooth is the tooth tip, as long as the replacement tool is sharp.

The more commonly used international brand excavators in the market are Carter, Komatsu, Hitachi, Daewoo, Kobelco, Hyundai, etc.

Commonly used China excavators are XCMG, Yuchai, SEM, Sany Heavy Industry, Lingong, Shantui, Foton Lovol, Liugong, Xiamen Engineering, Chenggong, Longgong, Shanhe Intelligent, Zoomlion, etc.

Bucket Teeth and Bucket Structure

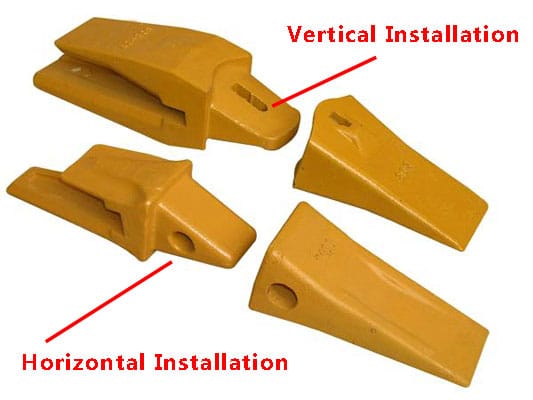

Now the bucket teeth of excavators generally have two structural forms, namely vertical installation type and horizontal installation type.

The vertical installation type refers to the vertical installation of the pin shaft and the front of the bucket teeth.

Horizontal installation means that the pin shaft is installed parallel to the front of the bucket teeth.

As shown in the figure, the tooth pin is directly mounted: this method is more convenient to disassemble. It is directly smashed from the top, and the operating space is large. When excavating, the straight-mounted tooth pin will be squeezed by the excavated material on the front. If the excavation force is large, the clamping force of the expansion spring cannot meet the requirements, which will easily cause the tooth pin to fall off. Therefore, although this structure is easy to disassemble, generally Used on excavators with smaller excavators and lower tonnage.

As shown in the figure, the tooth pin horizontally mounted type: it is not very convenient to disassemble, and the side operation space is small. It is difficult to apply force. When disassembling a single bucket tooth, special long rod tools must be used for disassembly and assembly in sequence. During excavation, the front surface of the horizontally mounted tooth pin will not be subjected to the extrusion force of the excavated material. The excavation force that can be endured is relatively large. However, when the expansion spring is subjected to reciprocating lateral force during use, it is easy to wear and fail, resulting in the tooth The pin comes off. This installation method is generally more common when the digging force is more than 20 tons.

Left: a general tool to remove bucket teeth, right: a special tool to remove bucket teeth

Bucket Teeth Types

Excavator bucket teeth are classified according to their use environment: they can be divided into rock chisel bucket teeth (for iron ore, quarry.), standard long bucket teeth (for soil, sand, etc.), and Tiger Long bucket teeth (for coal mines). However, the shape of the bucket teeth of different brands of excavators also has its own characteristics.

Classification of bucket teeth according to use environment

| Sand,rock, gravel | earthwork, river sand | rock, permafrost |

| 20ton-40ton | 6 ton -40ton | – |

The function of bucket teeth

1. Protect the bucket as a whole.

The bucket teeth are wearing parts. Because the bucket wears a lot when shoveling soil and stones. Adding the bucket teeth protects the bucket. Just imagine what a bucket without bucket teeth would wear…

2. Make the operation more delicate.

3. Easy to dig and shovel. The bucket teeth are conical. There is space in the middle. The force of the entire bucket. The active surface is smaller. The pressure is larger. It is easier to shovel and dig things…

4. After digging hard things, it has a buffering effect on the whole machine.